3-axle walking floor semi-trailer

Product benefits and optional extras

- Quality product made in Austria

- Weight-optimized, hot-dip galvanized short steel chassis for maximum payload and maximum volume

- bolted-on rear bumper

- Light brackets and attachments screwed to the rear.

- OPTIONAL: Axle lift on the 1st or 3rd axle, or on both the 1st and 3rd axles

- OPTIONAL: Lightweight steel or aluminum frame

- OPTIONAL: 13 pairs of recessed floor lashing rings, recessed on the sides

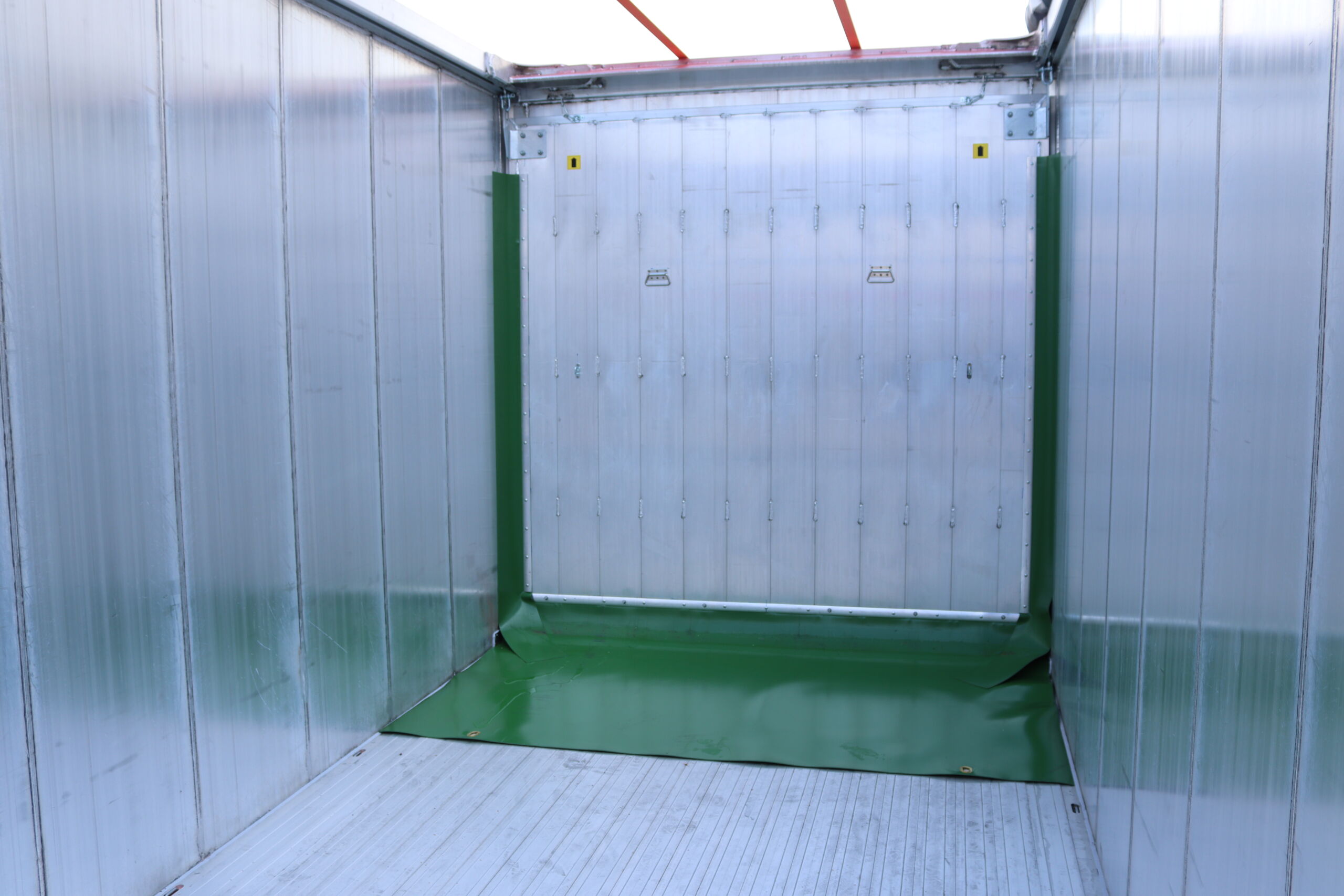

- OPTIONAL: Ground protection tarpaulin, pneumatically rollable, mounted at the rear for protection

- OPTIONAL: Rear upper crossbeam optionally swivels – can be operated from the ground

- OPTIONAL: Side wall with wedge-shaped wear plate on the inside, 1500x3000 or 1500x6000 (HxL)

- OPTIONAL: Roll-up tarpaulin stops, straight or cranked

- OPTIONAL: Side wall protection tarpaulin on the left side in the direction of travel

- OPTIONAL: Grain chute on the left or right in the direction of travel

- OPTIONAL: Cleaning door on the front wall

- OPTIONAL: Towing eye at the rear

- OPTIONAL: Crossbar design for waste transport 80 mm

- OPTIONAL: Positioning of the central control unit (lifting/lowering, safety locking, etc.) at the rear left

- OPTIONAL: Work lights, reversing lights, cargo area lights

Vehicle details

WEIGHTS

- Unladen weight from approx. 7.2 t

- Total permissible train weight 40 t

- Total weight (technical) 39 t

- Axle unit load (technical) 27 t

- Fifth wheel load (technical) 12 t

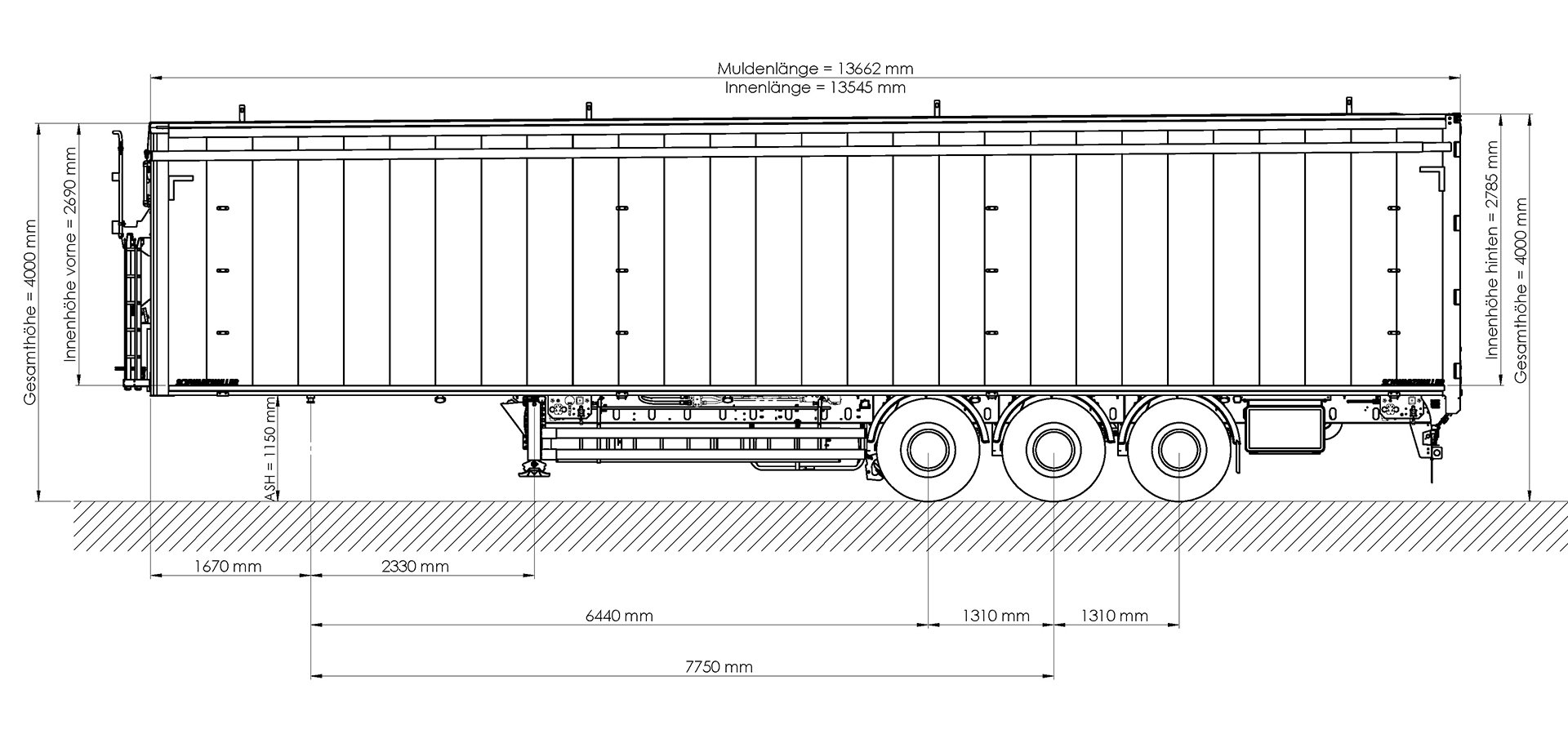

VEHICLE DIMENSIONS

- Internal length approx. 13,545 mm*

- Internal width approx. 2,480 mm*

- Interior height at the front approx. 2,690 mm*, at the rear approx. 2,785 mm*

- Loading volume approx. 92 m³

- Front turning radius 2,040 mm (EC installation dimension)

- (*Interior length without partition wall, interior width between upright side wall profiles, interior height measured to top edge of top chord)

FRAME

- short steel or aluminum frame welded construction from the rear to the seat posts

- Replaceable 2" kingpin

AXLES/CHASSIS

- Installation of axles from renowned manufacturers such as SAF or BPW

- Air suspension as standard with lifting and lowering device (approx. +120/-80 mm)

- Automatic adjustment of the driving level from 15km/h

- Air suspension unit with low-maintenance disc brake axles, ø 430 mm,

- Axles: 3 x 9 t rigid, wheelbase 2 x 1,310 mm

- Tires:

- 6-speed 385/65 R 22.5

- 6 steel rims, 10-hole, ET120, silver

SUPPORT FACILITY

- mechanical 2 x 12 t support winches, single-sided operation and thrust compensation

BRAKE SYSTEM

- Braking system according to EC directives 71/320 or ECE R13

- Dual-line compressed air brake system

- EBS system Wabco 2S2M, one axle is sensing

- RSS/RSP - Stability Program

- Spring-loaded parking brake

ASSISTANCE/SAFETY SYSTEMS

- SWIT - Schwarzmüller Intelligent Telematics

- Axle load indicator via EBS CAN bus signal for display in the driver's cab

- Tire pressure monitoring according to ECE Directive 141

- Pneumatically operated safety lock on the rear doors

FLOOR

- Hydraulically adjustable aluminum profile floor for loading and unloading with a 200 mm stroke

- 21-board system in medium-weight design with profiled board thickness of 6-10 mm

- Floor operation via remote control – emergency operation on the left in front of the axles

- Requirements for the truck hydraulic system: approx. 110 l/min, operating pressure approx. 225 bar (pressure limiter to 250 bar), oil reservoir 150 l

- Hydraulic connections with DN 25 quick-connect coupling halves with 90° upward bend, front-mounted.

STRUCTURE / UNDERFLOOR CONSTRUCTION

- Load securing certificate according to DIN EN 12642 Code XL

- Standard rear floor reinforcement with additional cross members

- self-supporting aluminium construction with 30 mm aluminium hollow profile walls,

- Side wall profiles welded continuously along the entire height on the inside

- Partition wall that can be moved along its entire length

- Partition wall carriage with cleaning brushes

- 4 recessed, removable crossbars 60 mm, also suitable as tarpaulin supports

- Rear panel as a double-leaf door with one external rotary rod lock per door leaf

- Rear upper crossbeam fixed, optionally swiveling – operable from the ground

- Standing platform at the front wall with maximum step width, railing and access for roller shutter operation

Convertible top

- PVC roll-up tarpaulin in reinforced design (900g/m2) including aluminum slat with hand crank and 2 longitudinal tension straps

- Tarpaulin overhang at the front approx. 200 mm and on the left side approx. 400 mm.

- On the left side, with 4 tension straps including tension locks on the underside of the recess.

- Tarpaulin color according to availability

ELECTRICAL EQUIPMENT

- 24 Volt lighting system in accordance with ECE Directive R48

- Light carrier with 2 full-LED multi-chamber rear lights and 2 LED outline lights

- flashing LED side marker lights

- 2 LED position lights on the bottom of the front bulkhead

- 2 x 7-pin and 1 x 15-pin sockets

Painting / Lettering

- Multi-layer epoxy zinc phosphate primer and spray coating with 2-component polyurethane topcoat (RAL or truck standard color)

- Plastic parts and hot-dip galvanized parts, unpainted

- powder-coated mounting/installation parts, black

- Reflective contour marking stripe along the entire length of the sides and circumferential contour marking at the rear (standard white on the sides and red at the rear), according to ECE 48

- Rear marking according to ECE standard

ATTACHMENTS

- Rear screw-on aluminum bumper

- Wedge as per regulations

- Plastic mudguards with splash guards as per regulations

- Side-mounted, foldable impact protection made of aluminum profiles according to regulations.

- Fixed steel square tube underride guard, in accordance with EU Directive UN/ECE R58 R3

- Hinged protective flap for lighting on the light fixture

- "Schwarzmüller" rubber apron on the tubular underride guard

- Spare wheel carrier for 1 spare wheel

- Side-mounted standard plastic toolbox, approx. 800/500/500 mm

- retractable step at the rear right

- Aluminum access ladder approx. 3,000 mm

- Holder for shovel/broom on the side guard

- Central control unit (lifting/lowering, safety locking, etc.) on the left in front of axles

Impressions

3-axle walking floor semi-trailer with aluminum frame, optionally with electric roll-up roof

central tarpaulin closure with aluminum slat

Tarpaulin protection board to protect the roll-up tarpaulin during the loading process

Grain hopper in the rear door

Moving partition wall for complete emptying

Full LED lighting

Radio remote control with control of work lights or lift axle

Radio remote control with control of work lights or lift axle

Lightweight frame in steel or aluminium for maximum payload

Your Schwarzmüller contacts

Always close to you. We are here for you.

Premium customer service, too

From maintenance to rental vehicles