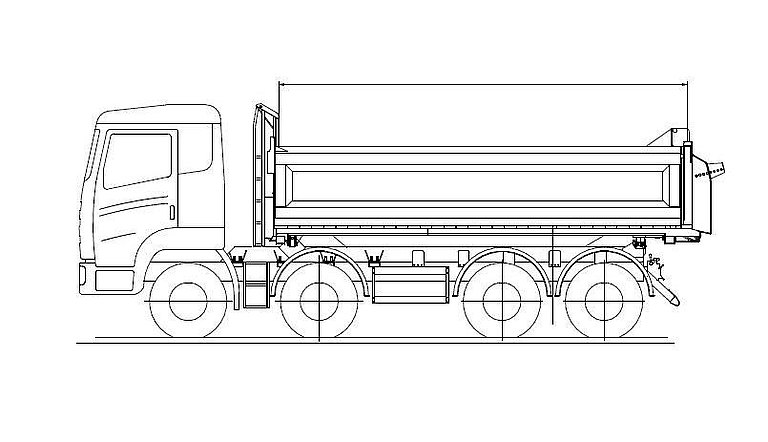

Left and rearwards tipping trailer on 4-axle truck

- Tipper body for for heavy rock use

- Torsion-resistant, weight-optimised subframe structure

- Hard chrome-plated, high-quality tipping cylinder

- OPTIONAL: Foldable lashing rings

- OPTIONAL: Foldable aluminium underride protection for road-finishing use

- OPTIONAL: Front crane assembly with reinforced subframe

- OPTIONAL: Without fixed corner post front left, left corner post integrated into side wall/Bordmatic

LEFT AND REARWARDS TIPPING TRAILERS ON 4-AXLE TRUCKS

for the transport of rubble, excavated earth, heavy stone

and occasionally bituminous mixtures/road-finishing use

Blasted with steel granulate, treated with zinc dust primer and spray painted with

2-component acrylic paints for commercial vehicles

Plastic and hot-dip galvanised parts unpainted,

powder-coated attachments/installation parts black

Reflective contour marking strips on both sides along entire length (continues over truck cab) and all-round contour marking at rear

(white on sides and red at rear as standard), according to ECE 48

Rear sign plate(s)

Tipper body rubber centre support

Brackets for wheel chock(s)

Spray protection using rubberised fabric, foldable, as per regulations

Aluminium cover on tail lights

Continuous side members with tilt cylinder bearings and outriggers

Connector lock for tipper body with cross-over protection

32 t tilt cylinder for 2-way tipping,

with safety rope

80 l pump for direct mounting,

60 l oil reservoir with oil filling,

pneum. tip valve with overpressure protection and actuation in cab

approx. 14.4 m³

Internal length: approx.

5,600 MM

Internal width: approx. 2,380 mm (incl. between posts)

External width: approx. 2,550 mm

Static and weight-optimised full-steel welded construction in

elastic membrane design

wear-resistant steel plate, type 450,

with continuously welded, closely ribbed trapezoidal struts below,

thus minimising weld distortion

approx.

6 MM

thick and approx.

1,250 MM

high

with solid supports and corner posts pointing forwards,

Cab protection with lashing eyes

and shovel bracket on front wall

plus

fixed ladder on outside front

Tapered corners inside front wall of body for transporting bituminous mixtures

continuous side wall made from approx. 85/6 mm thick

wear-resistant steel plate, type 450, approx.

1,080 MM

high,

right side wall

with tapering inside corners and

solid corner joints

as well as fixed chute side panel

= hydr. folding side wall 85/6 mm,

approx.

1,080 MM

high,

membrane construction made from fine-grained special steel panels (HB 450),

with dual-action cylinder on the front wall, operated from cab,

can be folded out to max. 170°,

autom. locking, non-swinging

Short side wall chute panel at front to limit direction of dumped

materials to the front

with hydr. locking controlled by dual-action cylinder and

pneum. 3-way valve

made of wear-resistant steel,

raised pendulum mount

with pin retainer, removable under specific conditions, approx. 50 mm gap to floor

reinforced corner post at rear,

with fixed side panel for discharge chute

Deflection wedges to corner posts on both sides

Your Schwarzmüller contact persons

Always nearby. We are delighted to help.