3-axle platform semitrailer - extendible

- Pull-out, 6,000 mm lightweight frame for transporting long materials up to 22 m

- Torsionally rigid, pull-out welded steel frame structure with 7-point pneum. locking on semitrailer

- Rear pull-out frame, 1,500 mm, in form of light carrier with limited load bearing capacity

- 3rd axle in form of steering knuckle/friction-steered trailing axle incl. reverse gear interlock

- Installation of axles from well-known manufacturers such as SAF or BPW

- OPTIONAL: Perforated external frame with approx. 100 mm hole spacing, 50/30 mm slot, for securing 2 t per lashing point

- OPTIONAL: Rear pull-out frame, 2,500 mm, load capacity up to approx. 2 t

- OPTIONAL: RULASI = post-based load securing system with various rack positions

- OPTIONAL: Hydraulic forced steering = steering knuckle trailing axles, via fifth-wheel coupling with steering wedge and ball bearing turntable

- OPTIONAL: Steel plate squared timber box for 20 lengths of 80 x 80 mm squared timber, with access cover on both sides

3-AXLE PLATFORM SEMITRAILER RH200 - EXTENDIBLE

Gross train weight (perm.): 40 t

Gross weight (techn.): 39 t

Axle assembly load (techn.): 27 t

Fifth-wheel load (techn.): 12 t

Tare weight: approx. 7.8 t

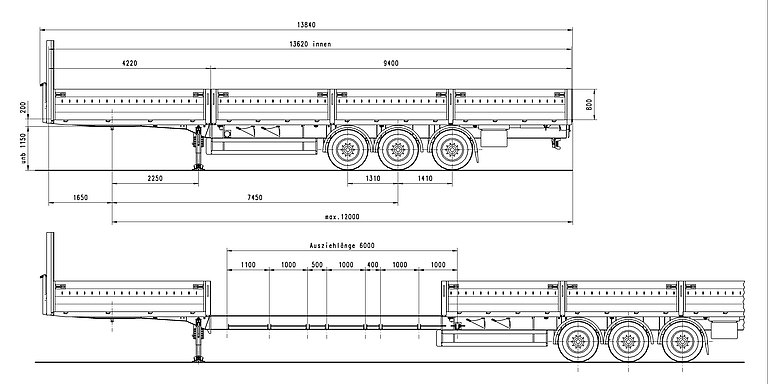

Internal platform length: approx. 13,620 mm

Internal platform width: approx. 2,480 mm

(platform length, front: approx. 4,220 mm, rear: approx. 9,400 mm)

Total width: 2,550 mm

Load space internal height: approx. 2,560 mm

Lateral loading height: approx. 2,500 mm

Rear loading height: approx. 2,560 mm

Loading height: approx. 200 mm over fifth-wheel height

Lightweight welded steel frame construction -

extendible up to 6,000 mm at spacing of

approx. 1,100/2,100/2,600/3,600/4,000/5,000 and 6,000 mm

Pneum. locking with operation on trailer - without intermediate support

Rearward extending frame = non-load-bearing light carriers,

extendible up to 1,500 mm, lockable every 500 mm

Frame for unladen fifth-wheel height of 1,150-1,250 mm with air-sprung STT (note total height)

Replaceable 2" kingpin (EC installation dimension, width across corners: 2,040 mm)

23 pairs of recessed 2.5 t lashing points according to UVV

Air suspension with lifting and lowering device (approx. +120/-80 mm)

Automatic adjustment of driving level from 15 km/h

air suspension unit with low-maintenance 430 mm disc brake axles, 3 x 9 t, wheelbase 1,310 + 1,410 mm

1st and 2nd axles rigid

3rd axle in form of steering knuckle/friction-steered trailing axle (12° steering angle) incl. electropneum. reverse gear interlock with autom. activation via reverse gear, also with switch activation in cab and operation on trailer

Tyres :

6 x 385/65 R 22.5 160J, manufacturer as per factory specifications

6 steel wheel rims 11.75 x 22.5, 10-hole, 120 mm rim offset, silver

Mechan. 2 x 12 t support jacks, single-sided operation and thrust compensation, manufacturer as per factory specifications

Brake system according to EC Directive 71/320 or E CE R13

Two-line brake

EBS - electronic brake system

Wabco 2S2M = one axle sensed

RSS - stability program

Spring-loaded parking brake

Steel air tank

Spruce softwood floor, 30 mm, lengthwise with aluminium omega profiles

Secondary floor made from resin-coated birch plywood, 9 mm, flush with external frame

Fixed aluminium hollow profile front wall, 1,700 mm, with 2 centre supports,

2 lashing rings inside for load securing

Front wall reinforced inside with galvanised steel plate, approx. 650 mm high

4-part aluminium hollow profile side walls, 800/25 mm (1-part at front, 3-part at rear), with rubber seal and bracket recess for tarpaulin overhang (360 mm), customs-compliant with tarpaulin brackets, foldable with latch-type tension locks 681-S1

Foldable aluminium hollow profile rear wall, 800 mm high, with rubber seal and bracket recess, customs-compliant with tarpaulin brackets, with latch-type tension locks 681-S1

2 folding steps

2 front corner posts, bolted, protruding from sides, 2,000 mm high

8 foldable centre posts, split

2 rear corner posts, bolted to sides, 2,000 mm high

4 rows of softwood slot-in slats, 100/27 mm, in pockets, 200 mm spacing

1 slat at front

Edscha sliding tarpaulin frame, forward-sliding = pushed together

in loading area, design height 95 mm

Edscha control rod, adjustable (bracket on interior side protection)

Customs tarpaulin made from high-strength Trevira fabric with translucent roof, incl. tarpaulin rope and assembly,

tarpaulin manufacturer as per factory specifications, tarpaulin colour according to availability

24 V lighting system according to EC Directive 76/756/E WG

2 seven-chamber tail lights in underride protection

2 three-chamber tail lights in pull-out frame

LED side marker lights

2 clearance lamps

2 contour lights on underride protection

2 x 7-pin and 1 x 15-pin sockets

Blasted with steel granulate, treated with zinc dust primer and spray painted 2-component acrylic paints for commercial vehicles (standard RAL or truck colour)

Plastic and hot-dip galvanised parts unpainted,

powder-coated attachments/installation parts black

Reflective contour marking strips across entire length of sides and all-round contour marking at rear (white on sides and red at rear by default), according to ECE 48

Rear markings as per ECE standards (horizontal on rear doors/rear wall)

Rear crash guard

Side wall stop buffer

4 wheel chocks

Single wheel plastic mudguards with spray protection as per regulations

Aluminium underride protection, coated white

Side impact protection made from aluminium profiles as per regulations, coated black

1 spare wheel bracket for 1 spare wheel

1 plastic toolbox, lockable, unpainted

Your Schwarzmüller contact persons

Always nearby. We are delighted to help.